- Product Center

PE Battery Separator

AGM Battery Separator

PVC Battery Separator

EFB Battery Separator

Tubular Battery Gauntlets

Battery Flame Arrestor

Vent Plug For Battery

Battery Indicator

Battery Additive

Rubber Components For Battery

Battery Container

Battery Terminal

Charger and Discharger Machine

Lead Acid Battery Acid Gel Filler

Automatic Enveloping And Stacking Machine

Battery Assembly Line

Battery Testing Machine

Battery Environmental Protection Machine

Other Battery Machines

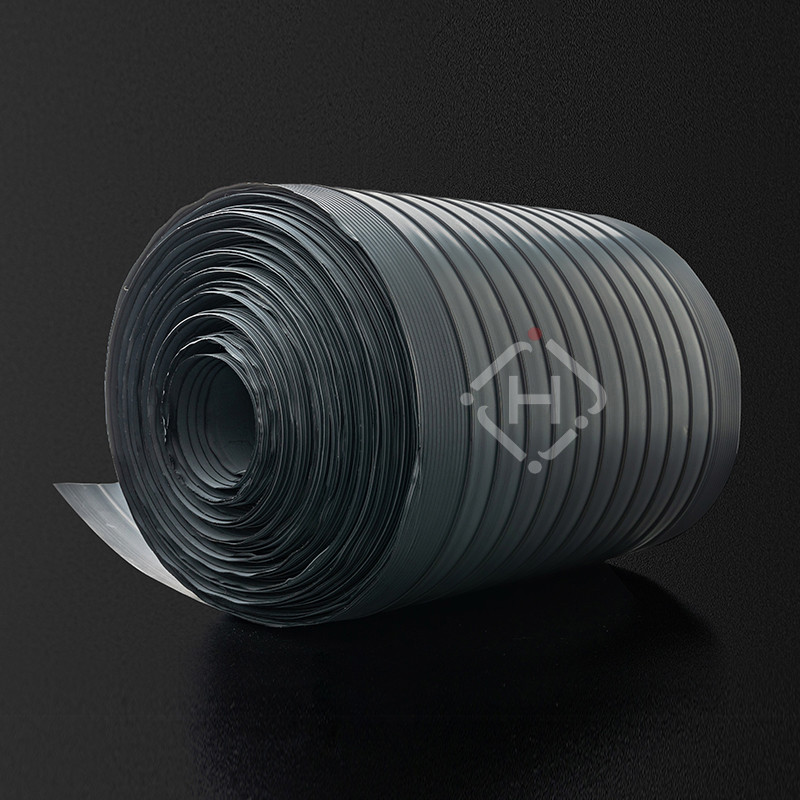

PE Battery Separator

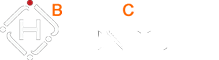

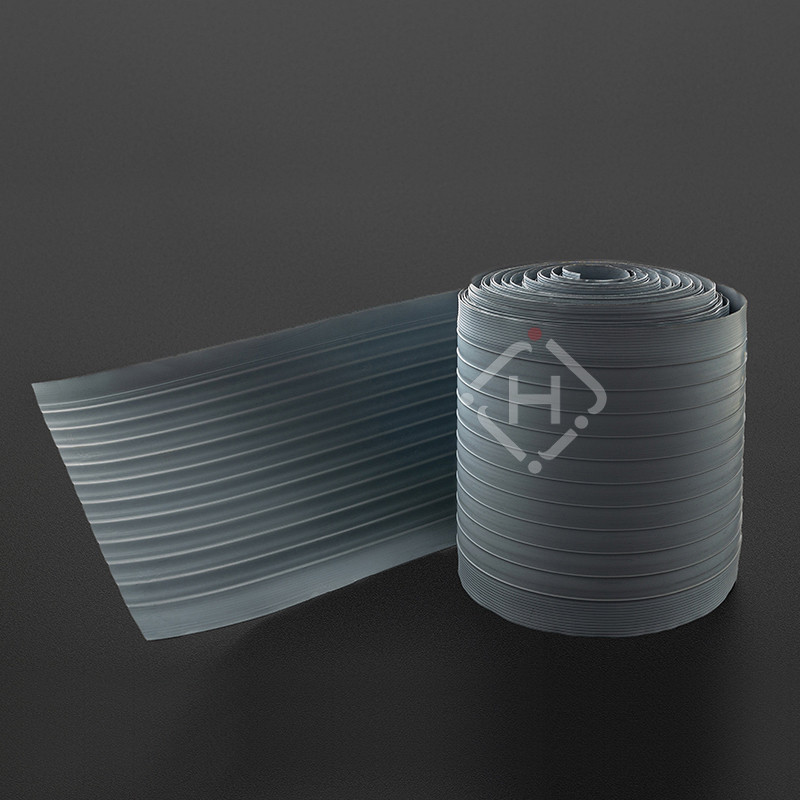

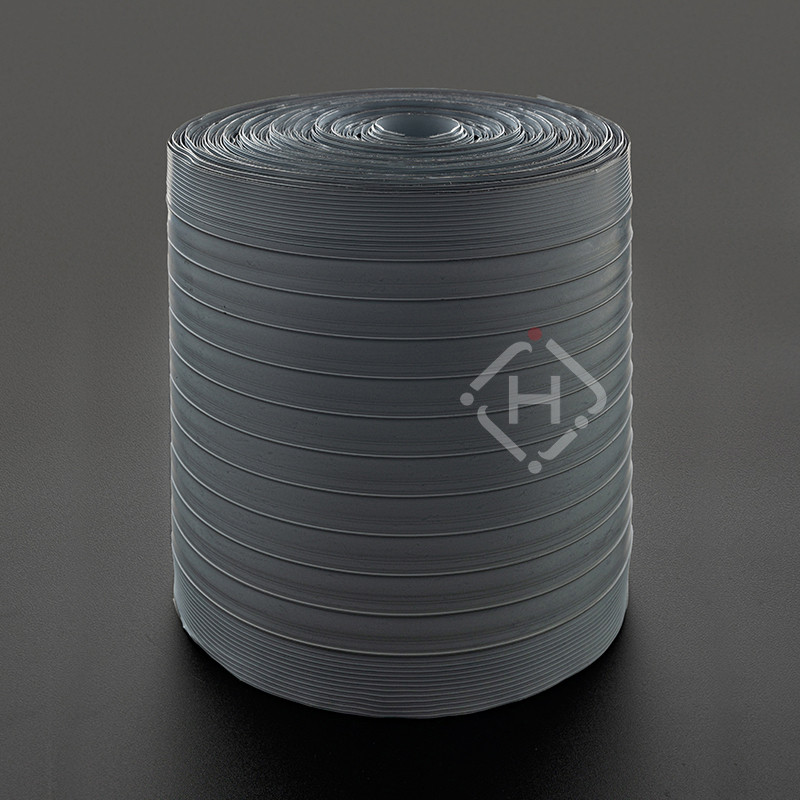

PE Battery Separator Roll

follow us

Overview

Specifications

FAQ

Quick Details

Automotive PE Battery Separator for Car Battery

Place of Origin: China

Brand Name: JHTD

Model Number: PE battery separator roll

Application: Consumer Electronics,Golf Carts,

SUBMARINES, Electric Bicycles/Scooters,

Electric Folklifts,vehicles, wheelchairs,

Electric Power Systems, Solar Energy

Storage Systems Uninterruptible Power Supplies

Roll length: 1200 /1150 /1100 /1050 /1000m

Total thickness: 0.8/0.9/1.0/1.1/1.2mm

Puncture Resistance: ≥8 N

Porosity: ≥55%

B/W Oil Content: ≥8%

O/W Oil Content: 12%≤Total≤18%

Usage: Automotive

Size: General / Customized

Industrial PE Battery Separator for Lead Acid Storage Battery

Place of Origin: China

Brand Name: JHTD

Model Number: PE battery

separator roll

Battery Size: Lead Acid Battery

Weight: 28-33 kg/roll

Elongaton (CMD): ≥300%

Electrical Resistance: ≤0.0015Ω.d㎡

Porosity: ≥55%

B/W Oil Content: ≥8%

O/W Oil Content: 12%≤Total≤18%

Moisture Content: ≤3.0%

Dimension Stability: ≤1.0%

Wetting Time: ≤60 s

Acid Weight Loss: ≤4.0%

Fe Content: ≤0.010

Usage: Industrial

Size: General / Customized

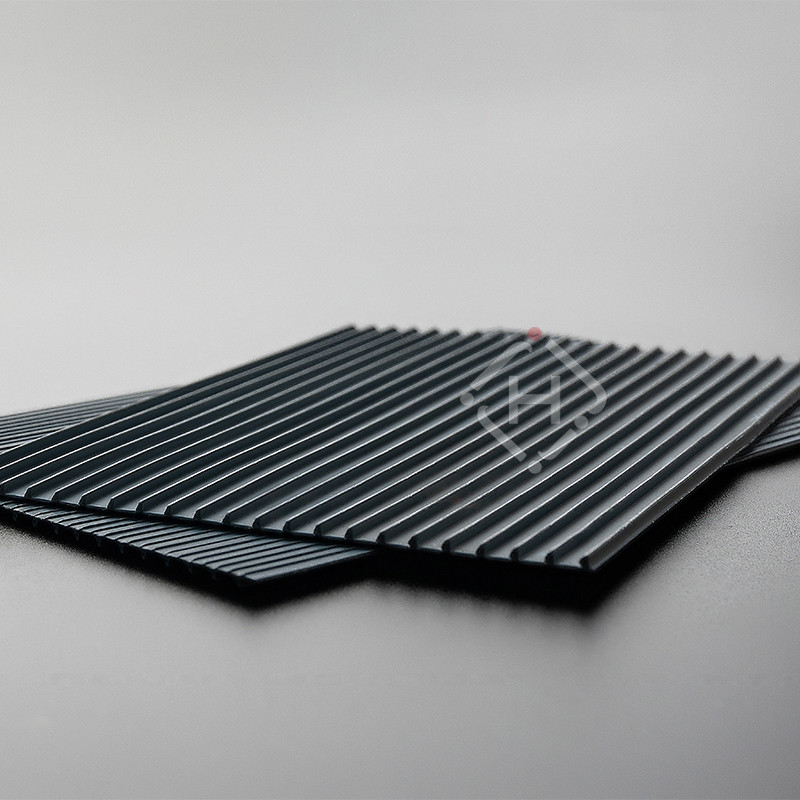

Feature

The mini ribs design makes the positive plate maintain more electrolytes, while negative plate keeps definite exhaustion, which can improve battery’s performance. Adapt to traction batteries and stationary batteries.

Q1: Why choose us?

We have over 15 years’ experience in the fiberglass industry . Excellent and stable quality with best cost performance. Our products have been known and accepted by more and more clients from all the world.

Q2: How long is your delivery time?

Samples: about 10 days.

Generally 20-30 days for mass production after sample confirmed and the receipt of formal PO or deposit.

Need Any Help

Leave your contacts and our engineers will help you to find the solution you are looking for.

English

English Russian

Russian Portuguese

Portuguese Arabic

Arabic Bangla

Bangla Indonesian

Indonesian